Your Total Manual to Preventing Weld Undercut Like a Pro

Your Total Manual to Preventing Weld Undercut Like a Pro

Blog Article

Understanding the Art of Welding: How to Stay Clear Of Undercut Welding Issues for Flawless Manufacture Results

By understanding the origin creates of undercut welding and executing effective strategies to avoid it, welders can raise their craft to new levels of quality. In the quest of perfect manufacture results, mastering the art of welding to avoid undercut concerns is not just an ability but a need for those aiming for excellence in their job.

Understanding Undercut Welding

To prevent undercut welding, welders ought to make sure appropriate welding criteria, such as readjusting the existing, voltage, traveling rate, and preserving the right electrode angle. By recognizing the reasons of undercut welding and applying preventative actions, welders can attain high-quality, structurally sound welds.

Reasons For Undercut in Welding

Comprehending the variables that contribute to undercut in welding is crucial for welders to produce top notch, structurally sound welds. Insufficient welding incorrect or present welding rate can additionally add to undercut. Comprehending these reasons and applying proper welding techniques can assist protect against damaging issues, guaranteeing strong and durable welds.

Techniques to stop Undercutting

To minimize the risk of undercutting in welding, welders can employ calculated welding strategies focused on enhancing the top quality and stability of the weld joints. One effective method is to adjust the welding parameters, such as voltage, existing, and take a trip speed, to make certain proper warmth input and deposition. Keeping an ideal electrode angle and ensuring regular traveling rate can likewise assist avoid undercut. Additionally, using the correct welding strategy for the details joint setup, such as weave or stringer beads, can contribute to lowering check this damaging. Preventing weld undercut.

Utilizing back-step welding methods and regulating the weld bead profile can likewise assist disperse warmth equally and reduce the danger of undercut. Routine assessment of the weld joint throughout and after welding, as well as implementing quality assurance procedures, can assist in detecting and attending to undercutting issues quickly.

Relevance of Proper Welding Parameters

Choosing and preserving ideal welding criteria is important for accomplishing effective welds with minimal issues. Welding criteria refer to variables such as voltage, current, travel speed, electrode angle, and shielding gas flow rate that directly affect the welding process. These criteria need to be meticulously changed based upon the sort of material being welded, its thickness, and the welding technique used.

Correct welding specifications make helpful resources sure the appropriate quantity of warm is put on melt the base metals and filler product evenly. If the criteria are established expensive, it can cause extreme heat input, creating spatter, burn-through, or distortion. On the various other hand, if the parameters are also low, insufficient combination, absence of penetration, or damaging may take place.

High Quality Assurance in Welding Procedures

Verdict

Finally, understanding the art of welding calls for a comprehensive understanding of undercut welding, its causes, and strategies to stop it. By making certain correct welding specifications and executing quality assurance techniques, remarkable construction results can be achieved. It is essential for welders to continually make every effort for excellence in their welding operations to stay clear of undercut problems and produce high-quality welds.

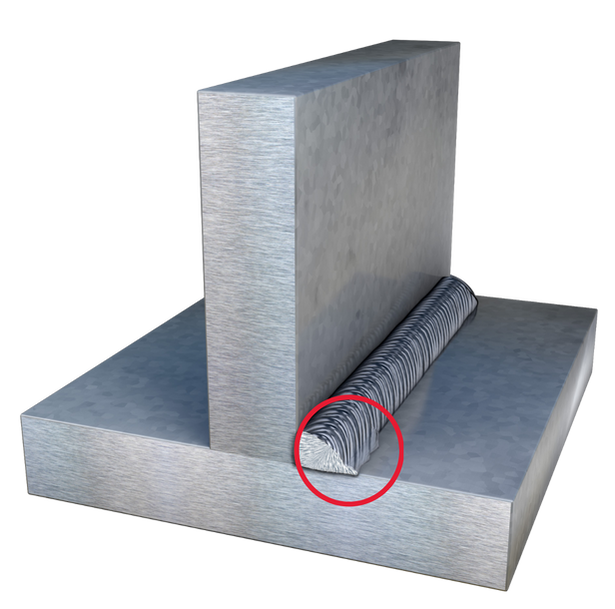

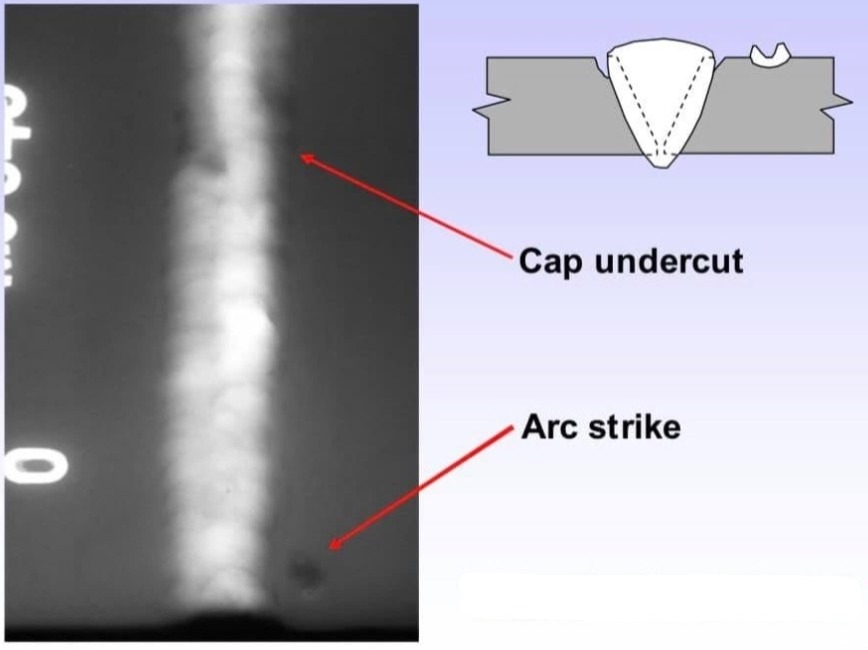

Undercut welding, an usual flaw in welding processes, takes place when the weld metal doesn't effectively fill up the groove and leaves a groove or anxiety along the bonded joint.To stop undercut welding, welders ought to make certain appropriate welding parameters, such as readjusting the present, voltage, travel rate, and maintaining the proper electrode angle. Insufficient welding inaccurate or current welding rate can additionally contribute to damage.To mitigate view it now the danger of damaging in welding, welders can utilize critical welding methods intended at enhancing the high quality and integrity of the weld joints.In final thought, grasping the art of welding requires an extensive understanding of undercut welding, its causes, and strategies to stop it.

Report this page